We are an Authorized dealer of Alankar Cable Industries make Linear Heat Sensing Cable, we offer LHS Cable for different types of application like Fuel Storages, Conveyor System, Cable Tray and Transformers.

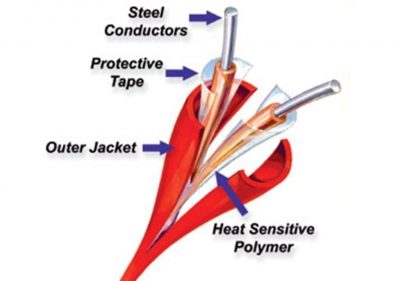

The heat sensitive polymer is protected by an outer jacket. Beneath this jacket and heat sensitive polymer coating is a pair of steel conductors. When the ambient temperature meets or exceeds the detector’s fixed temperature, the polymer melts. As it melts, the steel conductors make contact and initiate an electrical short that then sends a signal to the fire alarm panel of an alarm condition.

Linear Heat Detection (LHD) is a continuous heat detector designed to detect heat along the length of a sensor cable. This sensor cable is made up of two conductors, both insulated by heat sensitive polymers.

The heat sensitive polymer is protected by an outer jacket. Beneath this jacket and heat sensitive polymer coating is a pair of steel conductors. When the ambient temperature meets or exceeds the detector’s fixed temperature, the polymer melts. As it melts, the steel conductors make contact and initiate an electrical short that then sends a signal to the fire alarm panel of an alarm condition.

Once a signal has been sent, the panel will then release the fire suppression agent or set of the fire alarm system. For example, if the LHD is connected to a fire alarm that initiates the fire sprinkler system upon alarm, when the heat from fire melts the wire, the system is alerted, and the fire sprinkler valves open to allow water to flow in. LHD work with most any type of fire alarm system (wet, dry, etc.).

Applications

Fuel Storage

Conveyor System

Cable Tray

Transformers

Fuel Storage

Petroleum storage tanks and cryogenic storage facilities (liquid natural gas, LPG, ethylene, ammonia, etc.) require sensitive monitoring in order to allow for ample warning of elevated temperatures prior to combustion. By providing advanced notice of rising temperatures, appropriate steps can be taken to prevent disaster. Linear Heat Sensor are an ideal solution to fill this role.

The flexible Linear Heat Sensor cables can be directly mounted around the tank . The system provides real-time temperature monitoring and also detects the precise location of hot spots. As a result, safety personnel have real-time data of the thermal conditions of the storage tanks. This feature provides advanced warning and extra time for working personnel to counteract the repercussions of overheating.

Conveyor System

All conveyor systems are at risk of fire caused either by the ignition of transported materials or by equipment failure. A mechanical fault in the bearing of a roller, or the friction between the roller and the belt, can produce a build-up of heat sufficient to ignite a fire. In the case of a coal conveyor system, the risk of fire is exceptionally high.

Linear Heat Sensors are installed either on the side of the conveyor belt and/or above the idler arms. Linear Hot Spot Detectors can monitor the temperature of the conveyor and detect any hot spots along the belt; if a hot spot is detected, the HSD detectors will target the identified hot spots and trigger specific sprinkler systems to eliminate the condition of overheating.

Cable Tray

Power plants and industrial buildings often have miles of cable trays that carry power, data, and communication cables. Accumulation of heat from overloading, short circuiting, and aging cable often presents a fire hazard that can ultimately lead to lengthy downtime and even a large monetary loss. Cable trays are often stacked underground, above the ceiling, or through the walls. As a result, the trays often take tight turns and are frequently placed in contorted positions. Over time old trays need to be removed and new trays added. Therefore, any temperature monitoring system associated with the trays must be durable and flexible to accommodate these conditions.

Transformers

Overloading, aging, and poor cable contact can cause a transformer to overheat, often resulting in a fire disaster. As a result, a temperature monitoring system is the ideal solution to mitigate and prevent such disasters. The Linear Heat Sensors can be installed on the outer shell of the transformer by using a magnetic mounting kit.